Why a Rail ?

To maximize our points, we knew that being able to score samples and specimens optimally without sacrificing one for the other would be necessary. For specimen scoring, we found that being able to do cycles without having to turn the robot would save multiple seconds per cycle. Additionally, being able to score them without clipping down and moving the lift would save time. In order to accomplish both of these, a long arm is required on the deposit. However, having a long arm stick out the back of the robot would significantly reduce the amount of forward extension that we have. To be able to both reach far forward and not stick out the back, we needed a linear rail system to move the arm.

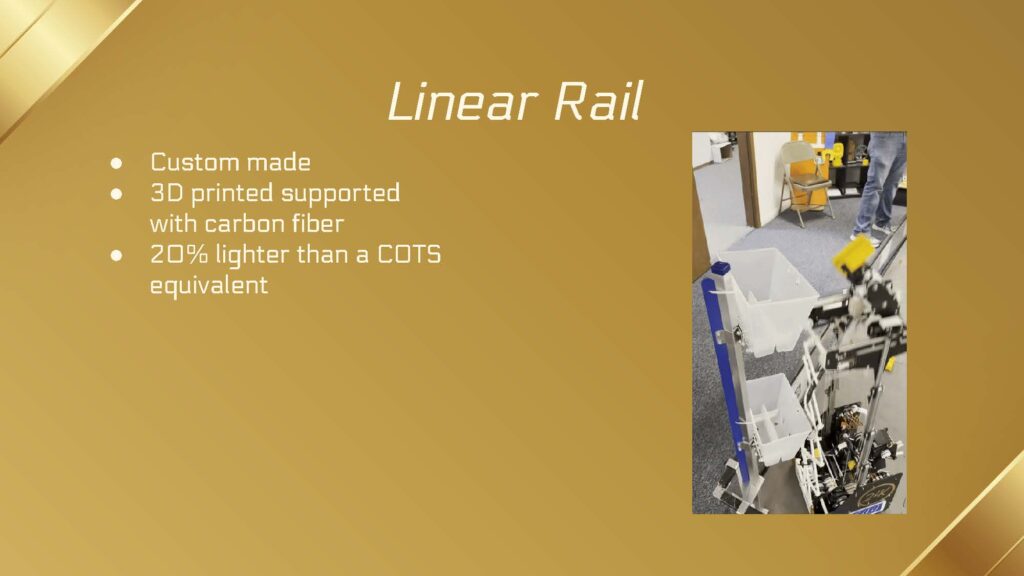

The unique nature of this system required a significant amount of designing, and manufacturing to be executed properly. We arrived to a 3 plate system which places constraints for the bearings which ride on an intermediate piece. These pieces we tested many times and tuned for manufacturing tolerances.

Why Differential ?

To limit the number of servos, maintain simplicity, and increase efficiency, our 2 bar arm + wrist subsystem utilizes a differential system. When the servos move together, they lift the 2 bar; When moving oppositely, they pivot the claw. This allows two servos to power both axes, doubling the torque and halving the load.